Ensure your shade structures stand the test of time with our essential guide on determining the proper depth for installation. Understanding the right footing and foundation depth is crucial for stability and durability, especially in varying weather conditions. Dive into our comprehensive resource to explore material recommendations, regional considerations, and best practices that will optimize your shade structures for lasting performance and value.

Comments (0)RSS

Blog

Discover how innovative shade structures can transform urban spaces into comfortable and inviting environments. Our exploration of different types of shade solutions highlights their role in enhancing pedestrian activity and sustainability while catering to diverse community needs throughout the year. Join us as we delve into advanced materials and creative designs that can elevate your city's public areas and encourage greater engagement.

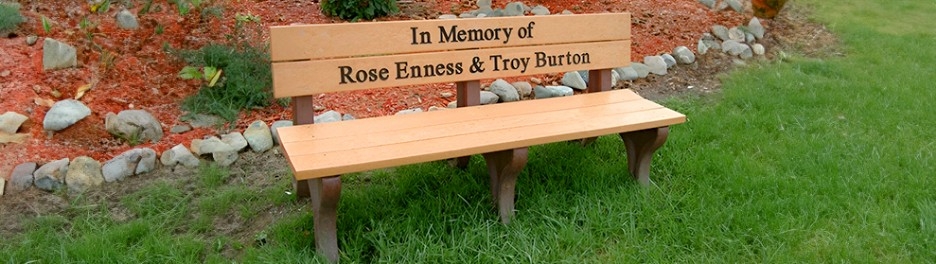

Comments (0)Explore the heartfelt significance of memorial benches as a way to honor loved ones in public spaces. These benches not only serve as lasting tributes but also create gathering places for reflection and remembrance, fostering a sense of community. Discover how thoughtful design and placement can enhance their impact, ensuring these meaningful installations provide comfort and healing for generations to come.

Comments (0)Exploring Modern Design Trends in Park Benches 18 Jan 2024

Dive into the world of modern park bench design, where creativity and innovation are redefining public spaces. Discover how sleek aesthetics, sustainable materials, and cutting-edge functionality are transforming these traditional seating staples into stylish and ergonomic masterpieces. Join us as we explore the most exciting trends in park benches that enhance both comfort and the overall outdoor experience.

Comments (0)Selecting the right bench styles for your commercial venue can significantly enhance the ambiance and functionality of your space. This comprehensive guide delves into the key factors to consider, ensuring you choose benches that harmonize with your environment and meet the needs of your patrons. Don’t miss out on valuable insights that will help you elevate your business's aesthetic and create inviting, comfortable seating areas!

Comments (0)Discover how custom commercial benches can serve as powerful tools for branding and memorialization in your public spaces. From engraved names and logos to personalized colors and materials, these benches can transform into meaningful fixtures that resonate with the community while subtly advertising your brand. Explore the myriad of customization options available to create functional seating that reflects your identity and honors cherished memories!

Comments (0)Ensure your park benches remain inviting and safe for community use by following essential seasonal maintenance tips. Regular care not only extends the life of these valuable public assets but also enhances the overall enjoyment of green spaces for everyone. Dive into our guide for best practices on maintaining outdoor benches and keeping your parks welcoming year-round!

Comments (0)Protect your community's public benches by understanding the importance of proper anchoring to prevent theft and unwanted movement. Securely anchored benches not only enhance safety and stability but also ensure that these valuable assets remain in place for everyone to enjoy. Learn more about effective anchoring solutions and how they can safeguard your public spaces!

Comments (0)Discover the various materials that make up park benches and how each choice impacts their appearance, durability, and maintenance. Selecting the right material is crucial for creating functional and inviting outdoor spaces that stand the test of time. Dive into our comprehensive guide to explore your options and make an informed decision for your park or public area!

Comments (0)Explore our comprehensive guide on implementing benches in sports facilities and parks to enhance the comfort and usability of these public spaces. Learn how to select the right materials and designs that can withstand heavy use and diverse weather conditions, ensuring longevity and satisfaction for community members. Don't miss out on these essential tips for creating inviting and functional environments for all to enjoy!

Comments (0)Blog search

Blog archive

- 2026

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017